The 5S methodology is a system or a step-by-step model for team members to follow. This framework is often considered the foundation of Lean manufacturing. It comes from the belief that for a business to achieve growth and success, it first has to remove the rotten fruit from within.

When following the 5s model, the organization’s goal is to build an effective structure and strategy so it can function as a whole and make it an easier place to work.

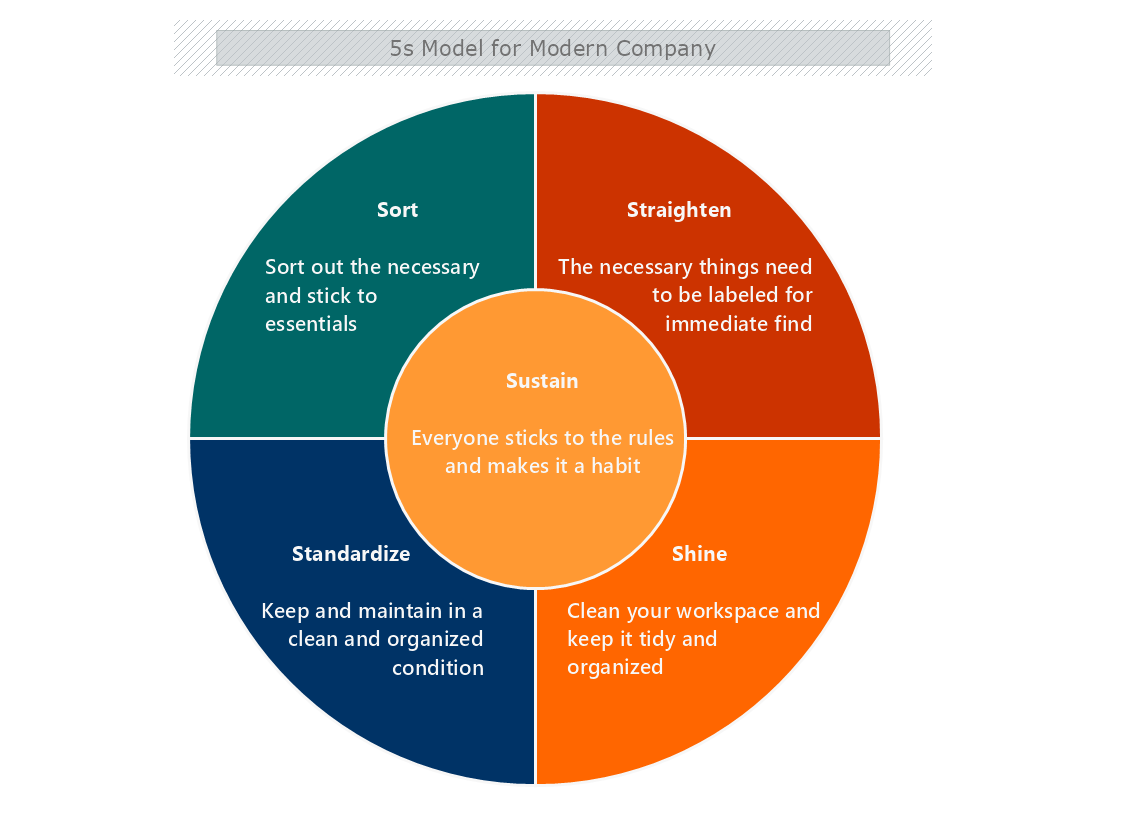

5S stands for the 5 steps of this methodology: Sort, Set in Order, Shine, Standardize, Sustain. These steps involve going through everything in a space, deciding what's necessary and what isn't, putting things in order, and building procedures for performing these tasks regularly.

NB: Some businesses choose to add this step at the end of 5S to ensure safety is a key component of work practices. Other businesses believe safety should be a part of all the steps of 5S and therefore doesn't need to be its step.